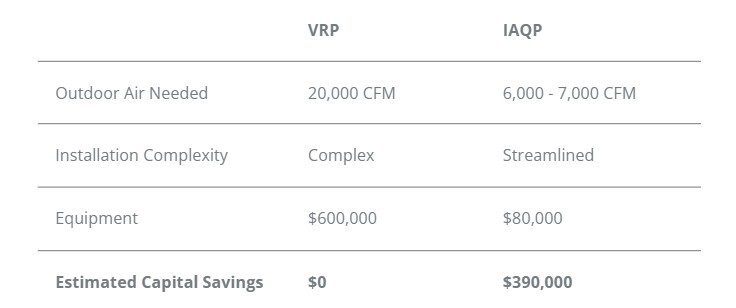

For this large K-12 school project, the engineering team explored value-engineering options to reduce mechanical costs without compromising ventilation quality. By shifting from a traditional Ventilation Rate Procedure (VRP) approach to the Indoor Air Quality Procedure (IAQP) supported by smartIAQ, outdoor air requirements dropped dramatically. This allowed the district to consider the downsizing of multiple DOAS units to achieve substantial first-cost savings.

A Texas school district was designing a new building with 20 classrooms and 11 science labs, averaging 1,000 ft2 each. The original mechanical design relied on a series of DOAS systems delivering all required outdoor air, with VRF fan coil units providing heating and cooling but no outdoor air of their own.

Under the Ventilation Rate Procedure, outdoor airflow for these spaces was nearly 20,000 CFM. In a high-enthalpy climate (common in Texas), conditioning volume of outdoor air is costly, energy-intensive, and often pushes HVAC systems beyond feasible or budget-friendly limits. The original design included:

As the engineering team and district reviewed the budget, they began searching for viable value-engineering options. The most promising pathway was to evaluate whether the Indoor Air Quality Procedure (IAQP) could reduce outdoor air requirements and significantly downsize capacity of multiple DOAS systems.

How K–12 School Saves with IAQP:

IAQP reduces required outdoor air volume

Design saves $400,000 in projected first cost

Meets ASHRAE 62.1 and code requirements

Delivers clean air with lower energy use

Under VRP, the design required:

VRP often leads to larger DOAS equipment, especially in schools where classroom ventilation requirements scale rapidly. In short, the VRP resulted in a high-cost, high-enthalpy design that strained budget feasibility.

Once IAQP was considered, the engineering team modeled contaminant loads and filtration performance using smartIAQ systems. This revealed that IAQP could safely and compliantly reduce outdoor air requirements by 65 to 70 percent, enabling a radically simpler and lower-cost mechanical design.

The revised IAQP-based design significantly reduced the capacity of all DOAS units. Proposed smartIAQ scope:

One smartIAQ Centralized system providing high-capacity side stream air cleaning to reduce outdoor air requirements and strengthen IAQP compliance for the entire school.

Estimated total smartIAQ cost: $80,000.

The engineering team determined that the smartIAQ-supported IAQP design fully met contaminant control requirements while significantly lowering both first costs and operational costs. As a result, the district is now strongly considering IAQP and smartIAQ as a VE alternative for the project.

The IAQP approach significantly outperformed VRP by reducing outdoor air requirements, dramatically reducing DOAS capacity, and lowering lifecycle energy use.

| HVAC Coil on Unit 3 | HVAC Coil on Unit 8 | |||

| Bacteria CFU/in2 | Mold-Fungi CFU/in2 | Bacteria CFU/in2 | Mold-Fungi CFU/in2 | |

| Swab 1 | 30,000,000 | 650,000 | 900,000 | 3,400,000 |

| Swab 2 | 20,000,000 | 500,000 | 20,000,000 | 2,800,000 |

| Swab 3 | 3,100,000 | 3,500,000 | 40,000,000 | 30,000,000 |

| Average | 17,700,000 | 1,550,000 | 20,300,000 | 12,066,667 |

This Texas school project demonstrates the significant impact IAQP can have in K-12 school environments, where VRP based ventilation requirements often drive higher capacity equipment and strain already tight project budgets.

By using smartIAQ to implement an ASHRAE 62.1 Standard-based IAQP design rather than defaulting to VRP, the engineering team reduced outdoor air requirements, radically reduced all DOAS capacity, simplified installation, and unlocked nearly $400,000 in capital savings, as well as an estimated $17,000 - $20,000 in energy cost savings annually.

For school districts evaluating alternatives to complex high-capacity systems or seeking cost-effective compliance with ASHRAE 62.1, IAQP provides a clear and proven path. With lower first cost, reduced energy consumption, and a leaner, more flexible mechanical design, IAQP and smartIAQ can provide a powerful alternative for school districts seeking high-performance ventilation and indoor air quality without the excessive capital cost burden.

Questions?