Levels of reduction shown in the results for all three criteria suggest a substantial potential benefit for the plant /product/occupant environment. In addition, previous scientific research has shown that the addition of ions into a grow space correlates to increased plant growth and yield in various crops.

The key objective of this study was to gain a deeper understanding of the benefits of GPS Air’s NPBI™ technology within grow facilities. The data collected can then be a key resource in the decision to implement NPBI into grow facility systems. To collect this data, the teams got together to set up and run the tests detailed below.

Prior to the test, the team gathered the following baseline observations:

Site Location: Southern US

Room Size: 3,553 ft2

Number of Plants: 880

Work Activity: Light activity (3) days / Heavy activity on 4/26

Light Cycle: 12 hrs On / 12 hrs Off

Days of Flower Cycle: 56-60

Environmental Conditions: 78°F / 74% RH

Background Ion Concentrations: < 200 ions/cc

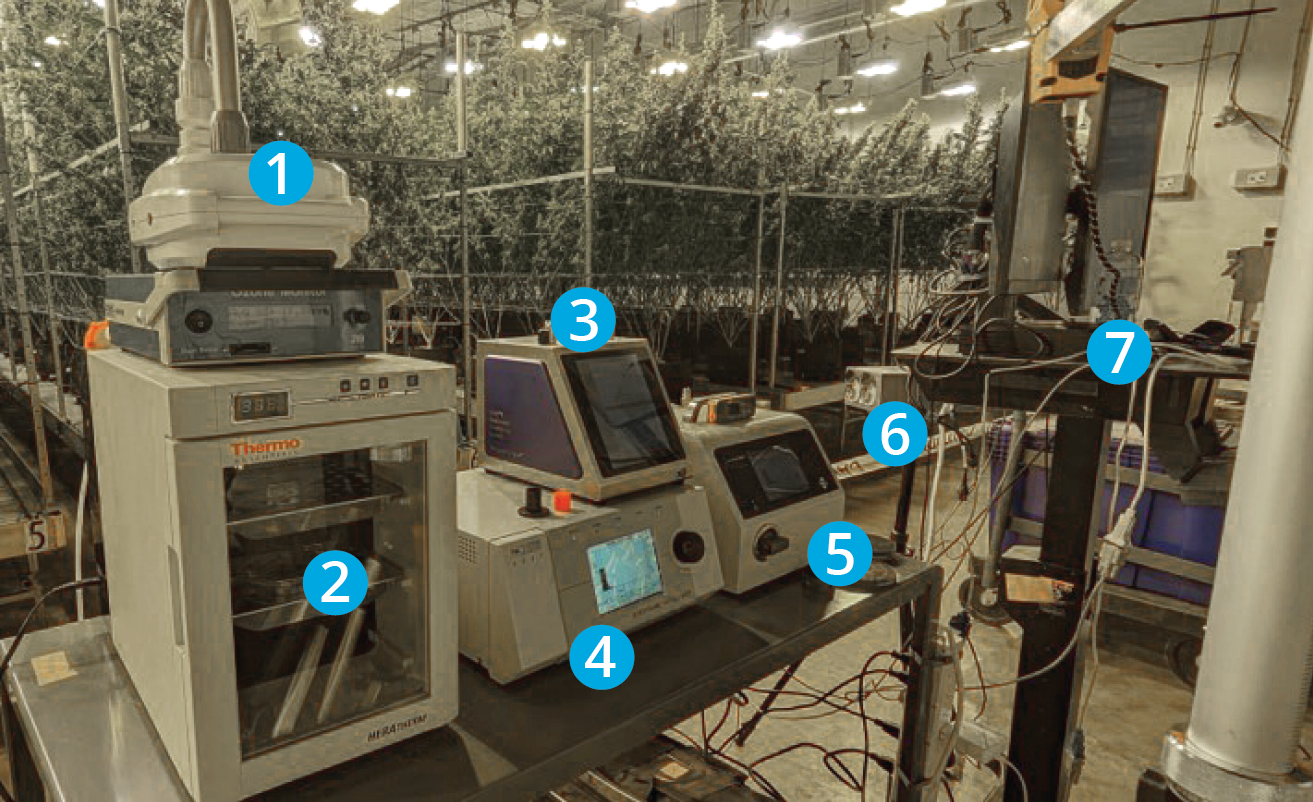

The test set up comprised of the following instrumentation (reference Figure 1):

1. Coriolis: Viable Mold and Bacteria

2. Incubator: Viable Bacteria

3. BAMS: Bioaerosols

4. APS: Fine Particulate

5. NanoScan: Ultrafine Particulate

6. COM-3800: +/- Ion Density

7. Control Center Panel: Network via Wi-Fi, Live Data Streaming, Data Logging, Remote Access/Monitoring

As shown in Figure 2, three destratification fans were employed with four FC-48 ionizers per fan.

The ion output at the fans was above 10 million ions, driving the average ion density within the space to be above 50 thousand ions/cc.

The fans were spaced to maximize air mixing, and ion levels were continuously monitored while ionization was applied during daily activity for a duration of three days.

The space in which the test occurred included the following HVAC/Air system configuration (reference Figure 3):

Five Ton DX Split Systems

22 AHU’s serving the space

MERV 10 filters installed on each AHU

50/50 ducted/non-ducted supply air

Anden De-humidifiers

12 total installed above canopy

MERV filters on return

Propane CO2 Burners in Space

2 burners installed above canopy

Air Circulating Fans (Perimeter)

10 total on each side

Figure 5

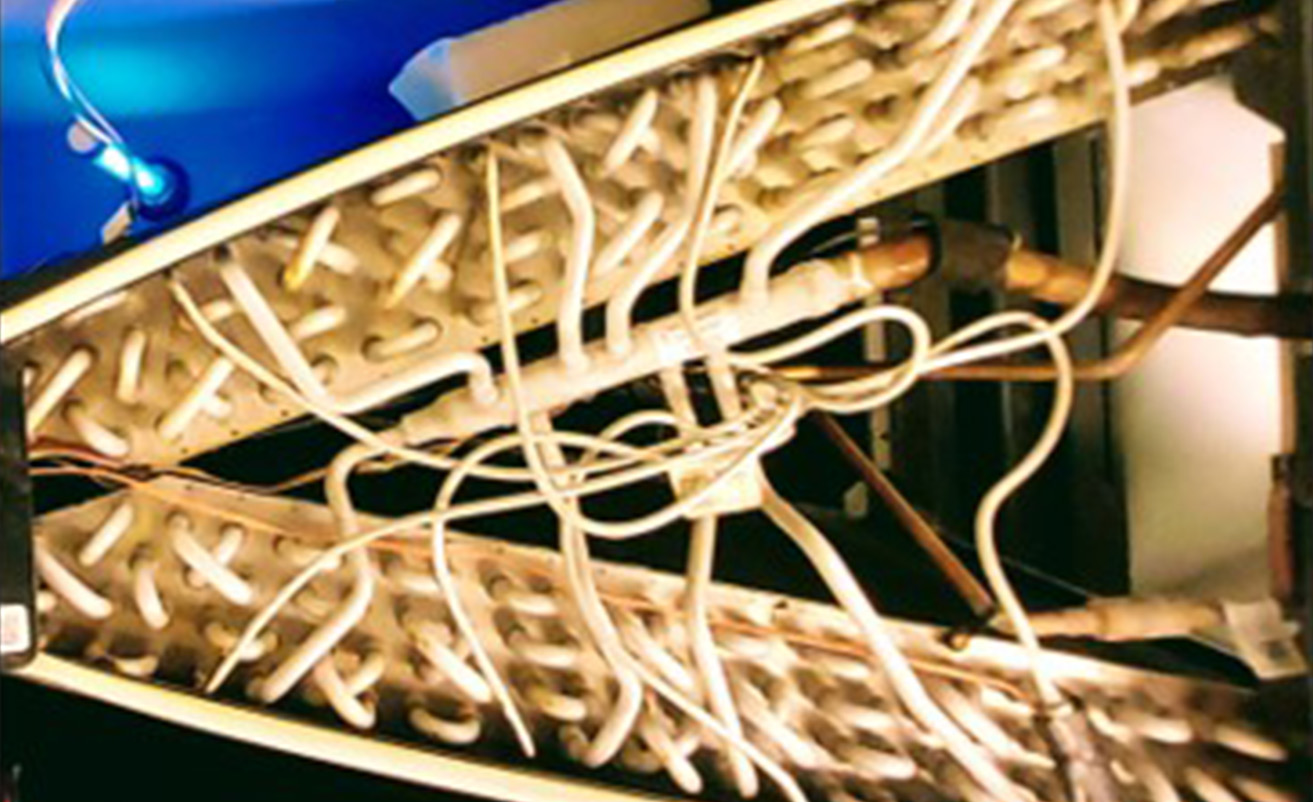

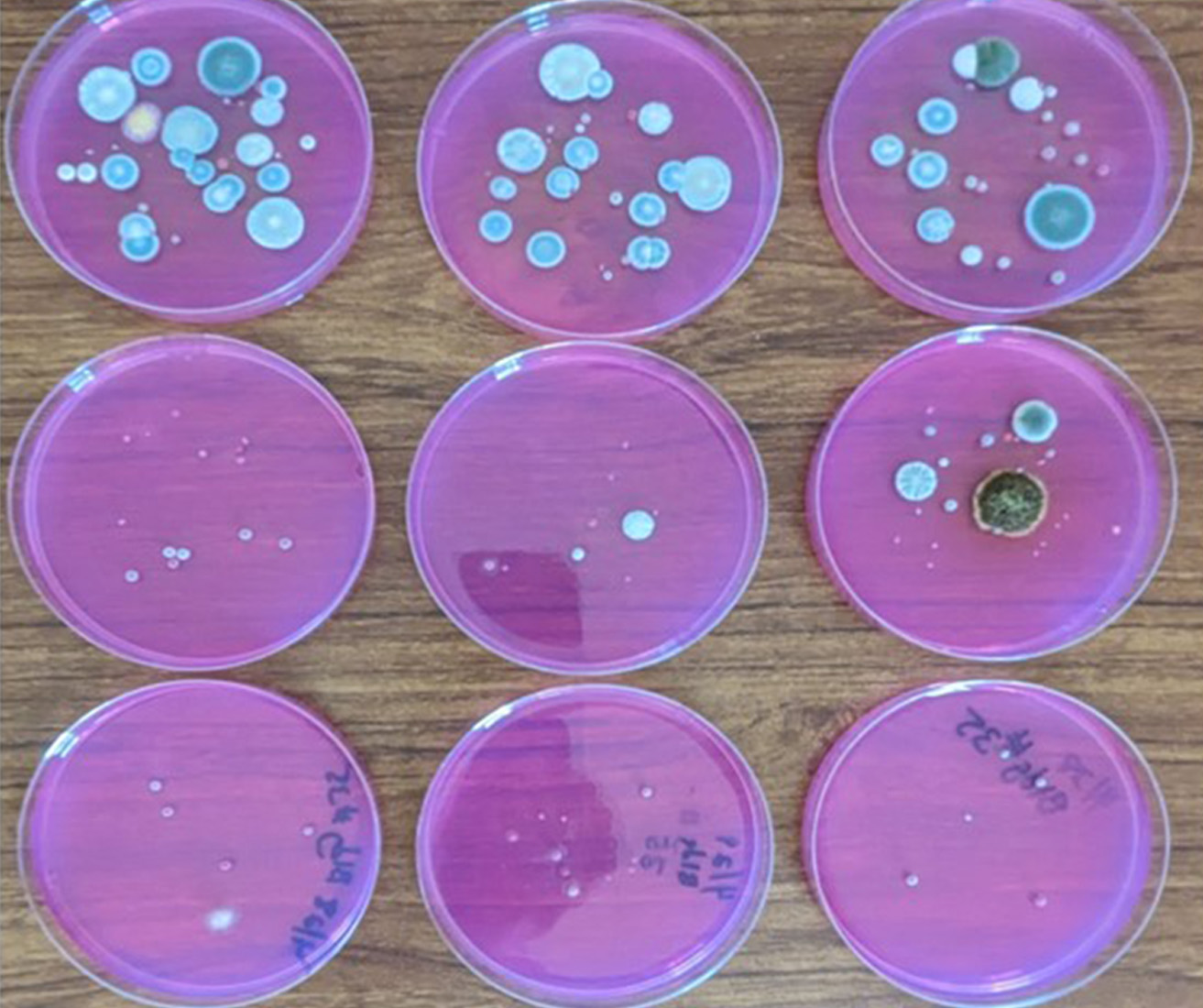

Prior to ionization, the team collected samples directly from the coil surface using sterile swabs. Two separate units were sampled.

Each unit had been in operation for only 2 years and housed UVC bulbs (shown in Figures 4 and 5) to prevent microbial colonization and biofilm growth.

Below is a chart that reports the viable concentration of bacteria and mold on the coils.

The Swab samples were analyzed and reported by an AIHA accredited environmental microbiology laboratory.

| HVAC Coil on Unit 3 | HVAC Coil on Unit 8 | |||

| Bacteria CFU/in2 | Mold-Fungi CFU/in2 | Bacteria CFU/in2 | Mold-Fungi CFU/in2 | |

| Swab 1 | 30,000,000 | 650,000 | 900,000 | 3,400,000 |

| Swab 2 | 20,000,000 | 500,000 | 20,000,000 | 2,800,000 |

| Swab 3 | 3,100,000 | 3,500,000 | 40,000,000 | 30,000,000 |

| Average | 17,700,000 | 1,550,000 | 20,300,000 | 12,066,667 |

The full test study ran for a total of five days, and included the following steps:

Setup & Calibrations

Take Baseline Measurements

Fans ON, Ionizers OFF

Active Measurement

IAQ Conditions

Data Trending

Fans ON, Ionizers ON

End of Study

Download of Data

Incubation of Culture Samples

| HVAC Coil on Unit 3 | HVAC Coil on Unit 8 | |||

| Bacteria CFU/in2 | Mold-Fungi CFU/in2 | Bacteria CFU/in2 | Mold-Fungi CFU/in2 | |

| Swab 1 | 30,000,000 | 650,000 | 900,000 | 3,400,000 |

| Swab 2 | 20,000,000 | 500,000 | 20,000,000 | 2,800,000 |

| Swab 3 | 3,100,000 | 3,500,000 | 40,000,000 | 30,000,000 |

| Average | 17,700,000 | 1,550,000 | 20,300,000 | 12,066,667 |

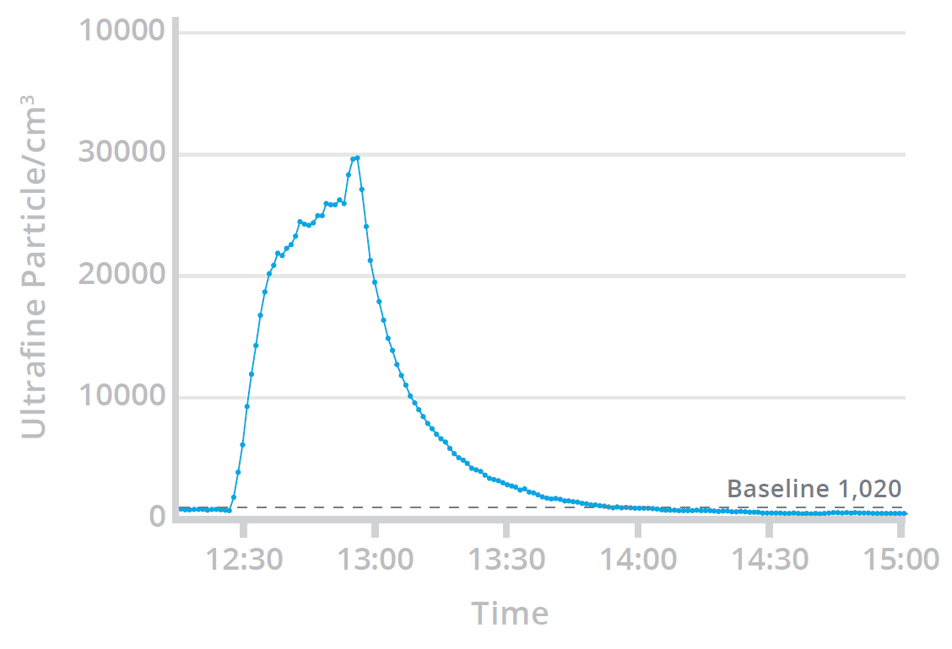

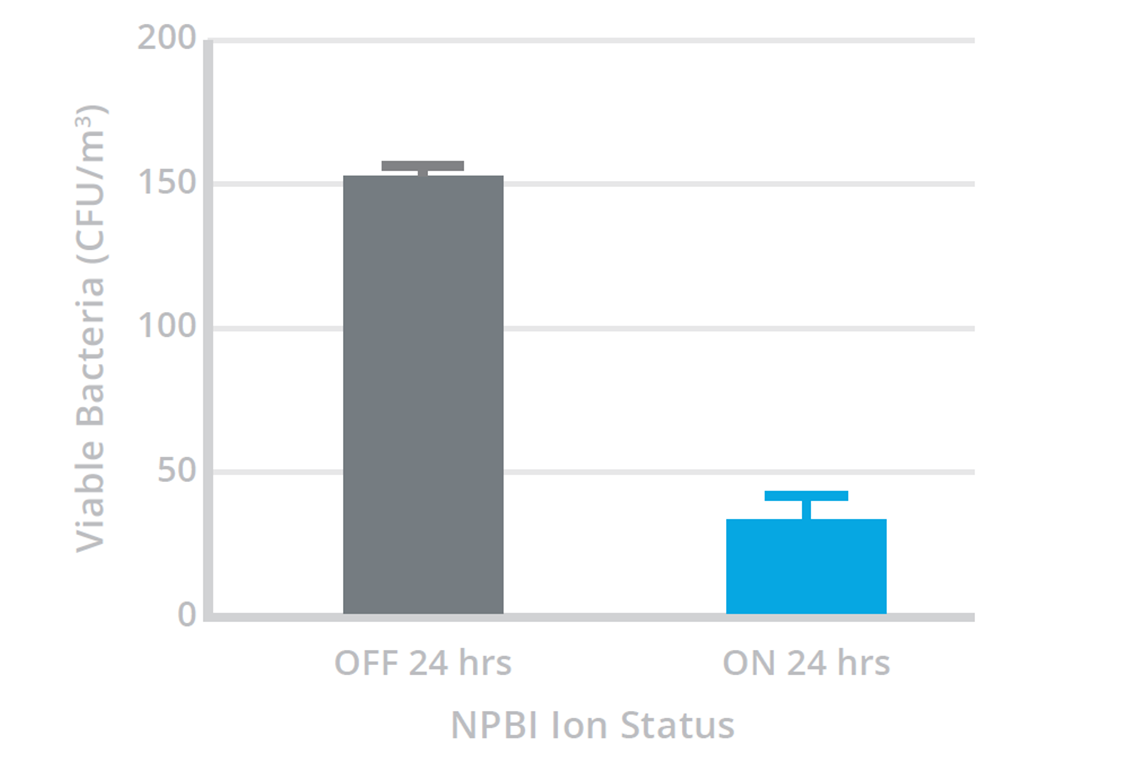

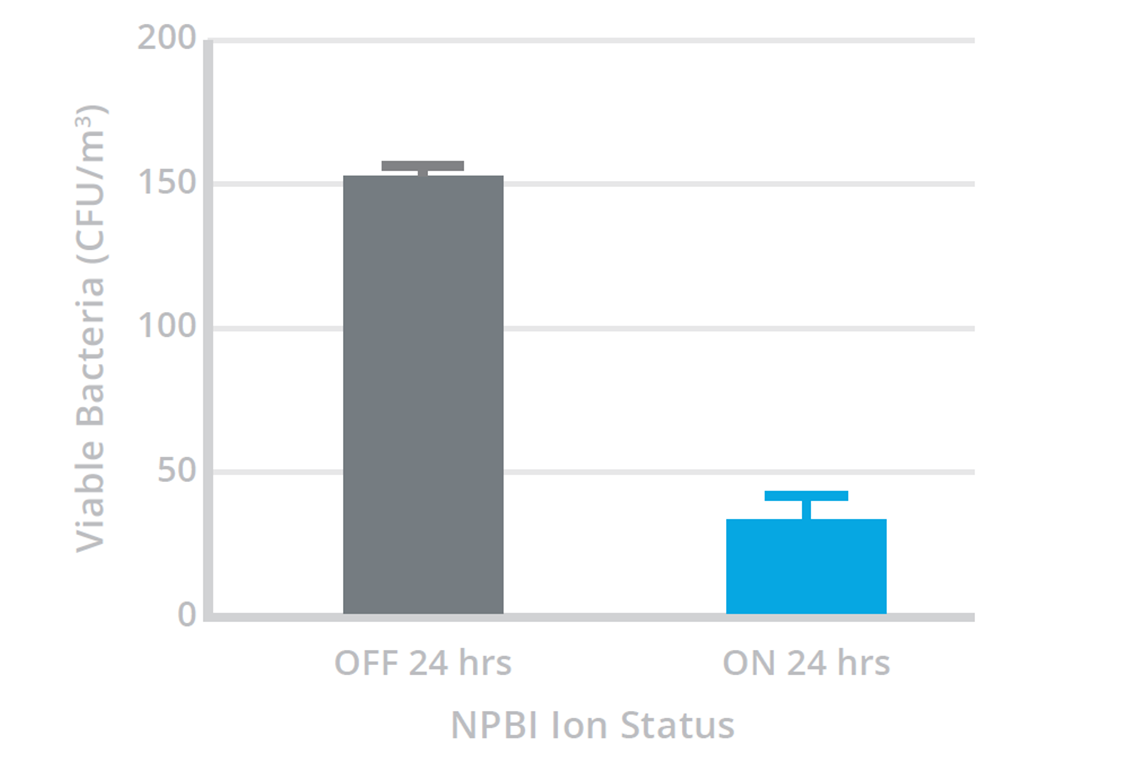

Using the APS and NanoScan particle counters, the team gathered a baseline reading, and looked at particle count spikes with and without NPBI. The results showed a significant decrease in ultrafine particles as shown:

% Reduction After 1 hr

w/ NPBI™ On

Control Sample (4-25)

24 hrs: Fans ON / Ions OFF

153 CFU/m3

Ionized Sample (4-26)

24 hrs: Fans ON / Ions ON

33 CFU/m3

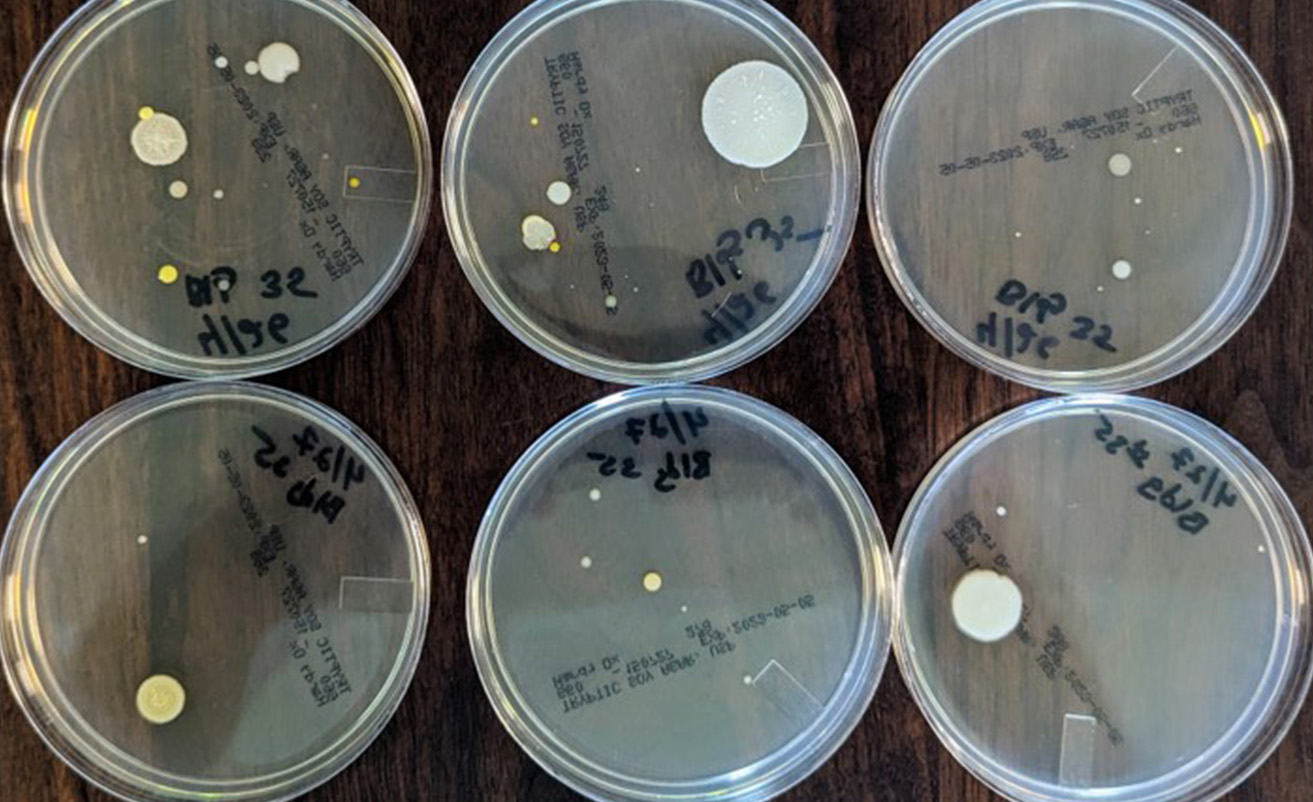

Triplicate samples were taken with and without treatment using NPBI technology, and showed compelling results in the reduction of airborne bacteria as shown:

% Reduction After 24 hr

w/ NPBI™ On

Significant decrease in viable bacteria detected. T-test analysis (P = 0.0012, t=20.78, df=2)

Control Sample

24 hrs: Fans ON / Ions OFF

306 CFU/m3

Ionized Sample

24 hrs: Fans ON / Ions ON

120 CFU/m3

Ionized Sample

48 hrs: Fans ON / Ions ON

13 CFU/m3

Triplicate samples were taken with and without treatment using NPBI technology, and showed compelling results in the reduction of airborne mold and fungi as shown:

% Reduction After 48 hr

w/ NPBI™ On

Significant decrease in viable mold and fungi detected.

ANOVA analysis (P = 0.0018, F=73.73, df=8)

This field study data shows significant reductions in fine/ultrafine airborne particles and viable mold/fungi/bacteria.

97% Particle Reduction - Excessive airborne particles negatively impact the respiratory health of employees. Reducing particle exposure decreases the incidence of allergic reactions and acute asthma in the employee population.

75% Bacteria Reduction - Airborne bacteria may affect employee health, but also contaminate flowers, cause plant diseases and contribute to biofilm formation in HVAC systems and various surfaces in grow facilities. Reducing airborne bacteria will improve the overall quality of the indoor grow facility and may result in a higher quality product.

78% Mold/Fungi Reduction - Airborne molds and fungi spread plant disease and contaminate flowers. Reducing concentrations is key to decreasing the incidence and spread of fungal diseases like powdery mildew and botrytis while increasing the overall quality of the final product.

Odor Mitigation via Reduction of Particles - Odors are associated with airborne particles generated from plant matter. Reducing these plant-based particles from the air can aid in the reduction of odor intensity. VOC’s such as airborne terpenes adsorb to airborne particles as well. Reducing particles concentrations via ion-induced agglomeration and VOC adsorption helps to reduce malodors indoors.

Plant Growth and Yield - Addition of Ions in scientific research has been shown to increase plant growth and yield in various crops (Elkiey, et al 1985, Krueger et al 1962).

Questions?