For this retrofit HVAC project, the engineer shifted from the traditional Ventilation Rate Procedure (VRP) to the Indoor Air Quality Procedure (IAQP) using GPS Air’s smartIAQ system. This approach lowered required outdoor air enough to eliminate the DOAS, creating a code-compliant ventilation design that stayed on budget and on schedule.

A private university in Texas acquired a four-story office building and planned to repurpose the first floor into classrooms and lecture halls. The existing HVAC system, served by two 70-ton AHUs with VAV and FPB terminals, had been designed for office occupancy of 125 people, not the 435-person load needed for the new academic program.

Using the Ventilation Rate Procedure in a retrofit HVAC application can dramatically increase required outdoor air and drive up mechanical costs. This was exactly the challenge the engineering team encountered.

In most retrofit HVAC projects, VRP pushes outdoor air far beyond what existing AHUs can support, forcing the addition of entirely new equipment. Under the Ventilation Rate Procedure, the first floor required 4,770 CFM of outdoor air to meet code. This triggered a major mechanical scope increase, forcing the engineer to consider two costly paths:

Ventilation Rate Procedure (VRP) Option 1:

Install a 25-ton DOAS, route new ductwork across the floor, and replace nine VAV/FPB units

Estimated cost: ~$500,000 turnkey

Ventilation Rate Procedure (VRP) Option 2:

Demolish existing ductwork, remove all terminals, and install a VRF/DOAS system

Estimated cost: $800,000–$1,000,000 turnkey

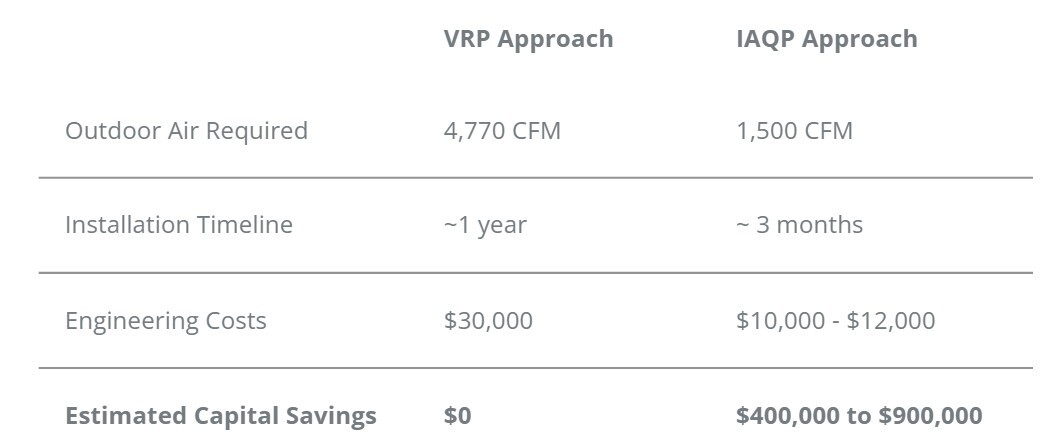

Both VRP strategies also increased engineering fees from $10,000 to $30,000 and added one full year to the project timeline due to design, equipment procurement, and construction sequencing. This is a common challenge in retrofit HVAC projects where existing air-handling equipment cannot support VRP outdoor air requirements.

Why IAQP Works in Retrofit HVAC Projects:

Reduces Outdoor Air Requirements

Avoids DOAS Additions

Uses Existing Air-Handling Units

Shortens Schedules

Reduces Ductwork Modifications

Cuts Capital Expenditures

After attending an IAQP training session, the design engineer revisited the project using a standards-based IAQP approach supported by smartIAQ. With standards-based contaminant modeling and filtration performance, outdoor air requirements were reduced from 4,770 CFM to 1,500 CFM.

This reduction eliminated the need for a DOAS unit and extensive new ductwork. The revised design kept the existing 70-ton AHU, requiring only routine repairs rather than replacement. smartIAQ provided the validated filtration and monitoring performance needed to meet IAQP contaminant limits.

The IAQP solution included:

Engineering fees returned to the original $10,000 - $12,000 budget, and the installation window dropped from one year to three months.

With IAQP implemented, the renovated classrooms are now on track to open for the Spring 2026 semester. Had the university pursued the VRP path, the space would not have opened until mid-2027. This is a clear example of IAQP outperforming VRP in a retrofit HVAC environment.

| HVAC Coil on Unit 3 | HVAC Coil on Unit 8 | |||

| Bacteria CFU/in2 | Mold-Fungi CFU/in2 | Bacteria CFU/in2 | Mold-Fungi CFU/in2 | |

| Swab 1 | 30,000,000 | 650,000 | 900,000 | 3,400,000 |

| Swab 2 | 20,000,000 | 500,000 | 20,000,000 | 2,800,000 |

| Swab 3 | 3,100,000 | 3,500,000 | 40,000,000 | 30,000,000 |

| Average | 17,700,000 | 1,550,000 | 20,300,000 | 12,066,667 |

This project illustrates how IAQP transforms retrofit feasibility. By applying a standards-driven, clean-air approach rather than oversizing outdoor air under the VRP, the engineering team avoided unnecessary equipment, preserved the existing AHU, eliminated a DOAS requirement, kept engineering fees within budget, and compressed the schedule by nearly a year.

This project demonstrates how the Indoor Air Quality Procedure can unlock simpler, lower-risk retrofit HVAC designs without compromising code compliance or air quality. smartIAQ allowed the university to deliver a fast, code-compliant, and cost-effective solution, proving that better air quality and lower project costs can go hand in hand.

Questions?