Through ionization, the iMod inhibits bacteria and mold growth on air handler coils. iMod’s bio-guard performance keeps a new coil clean longer or cleanses existing coils; saving energy through efficient heat transfer and reduced static pressure across the coil. This lowers fan power and other HVAC equipment stress (e.g. chiller pumps, compressors, etc.).

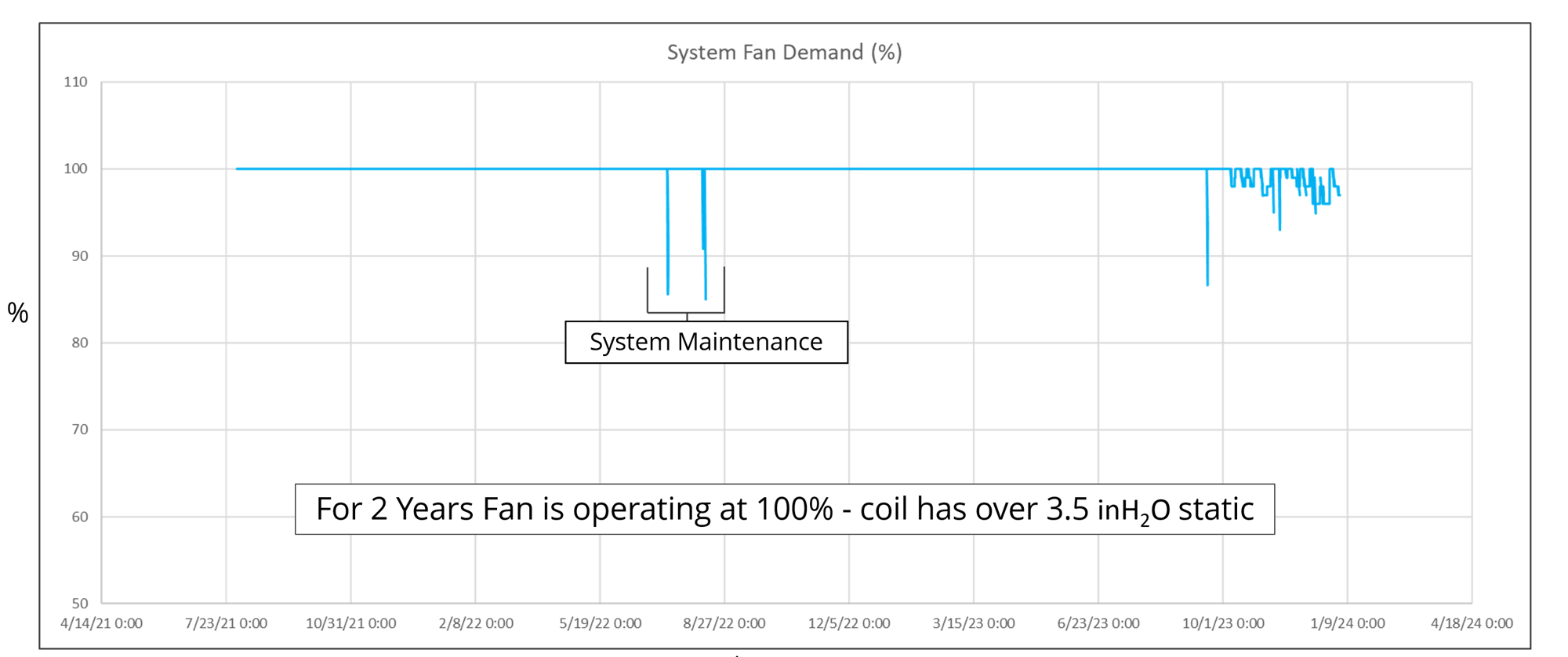

This 19-year-old facility has a chilled-water fed air handler that has been operating at maximum fan output for over 2 years because the coil is compacted at over 3.5” static pressure.

The system is unable to achieve desired temperature and humidity control. Patient and employee comfort is being challenged.

Exhausting other options, the owner is faced with a costly ($70,000) coil replacement.

Prior to pursuing the replacement:

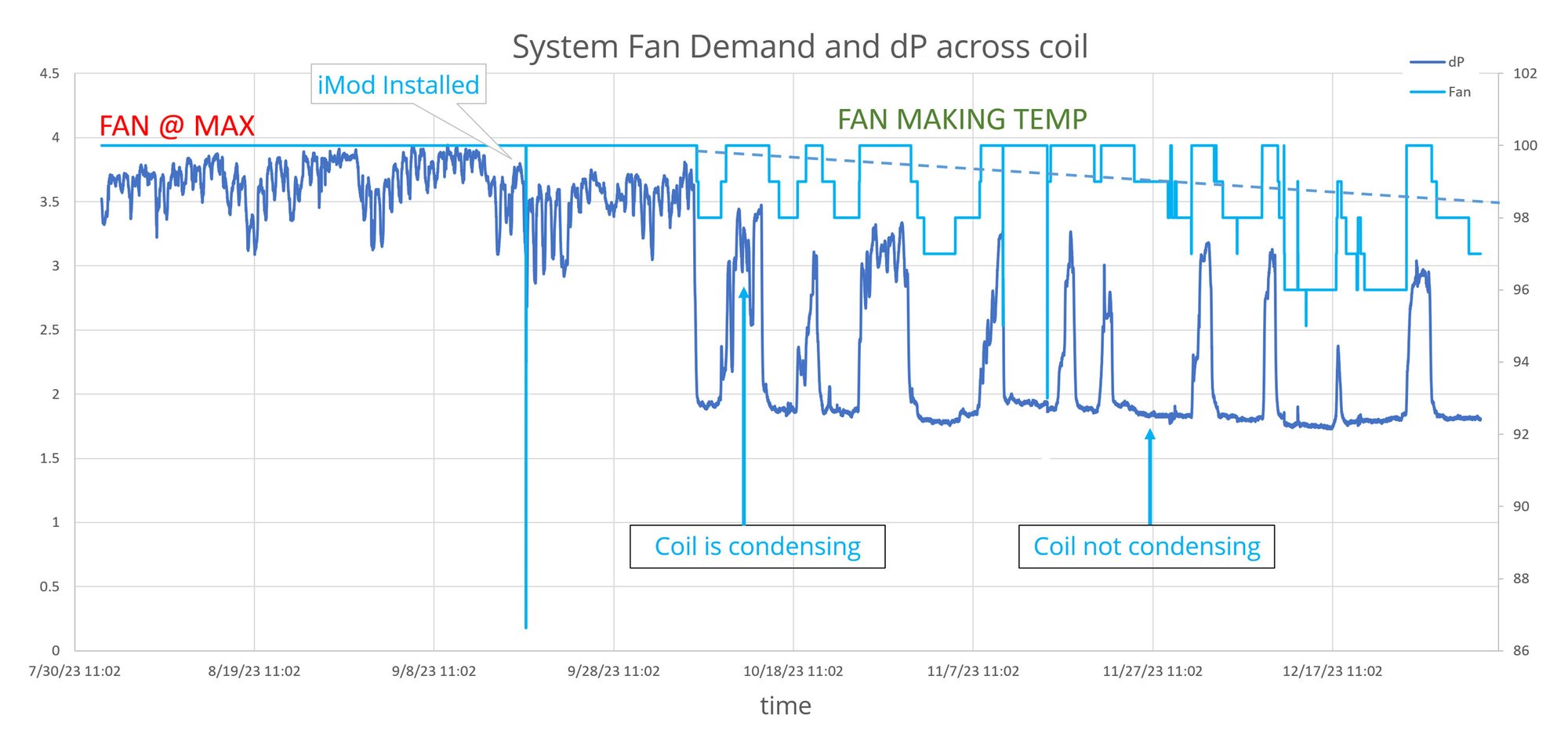

GPS Air and Novant Health partnered to conduct a test to improve the efficacy of the coil.

The goal was to increase the efficiency of the system through remediation, with the installation of a GPS Air Coil Efficiency System.

Taken together, the fan speed began to decline as both the maximum and minimum coil pressure drop began to decline. This indicates a reduction of static pressure due to the coil biofilm being reduced after the iMod was installed.

Questions?