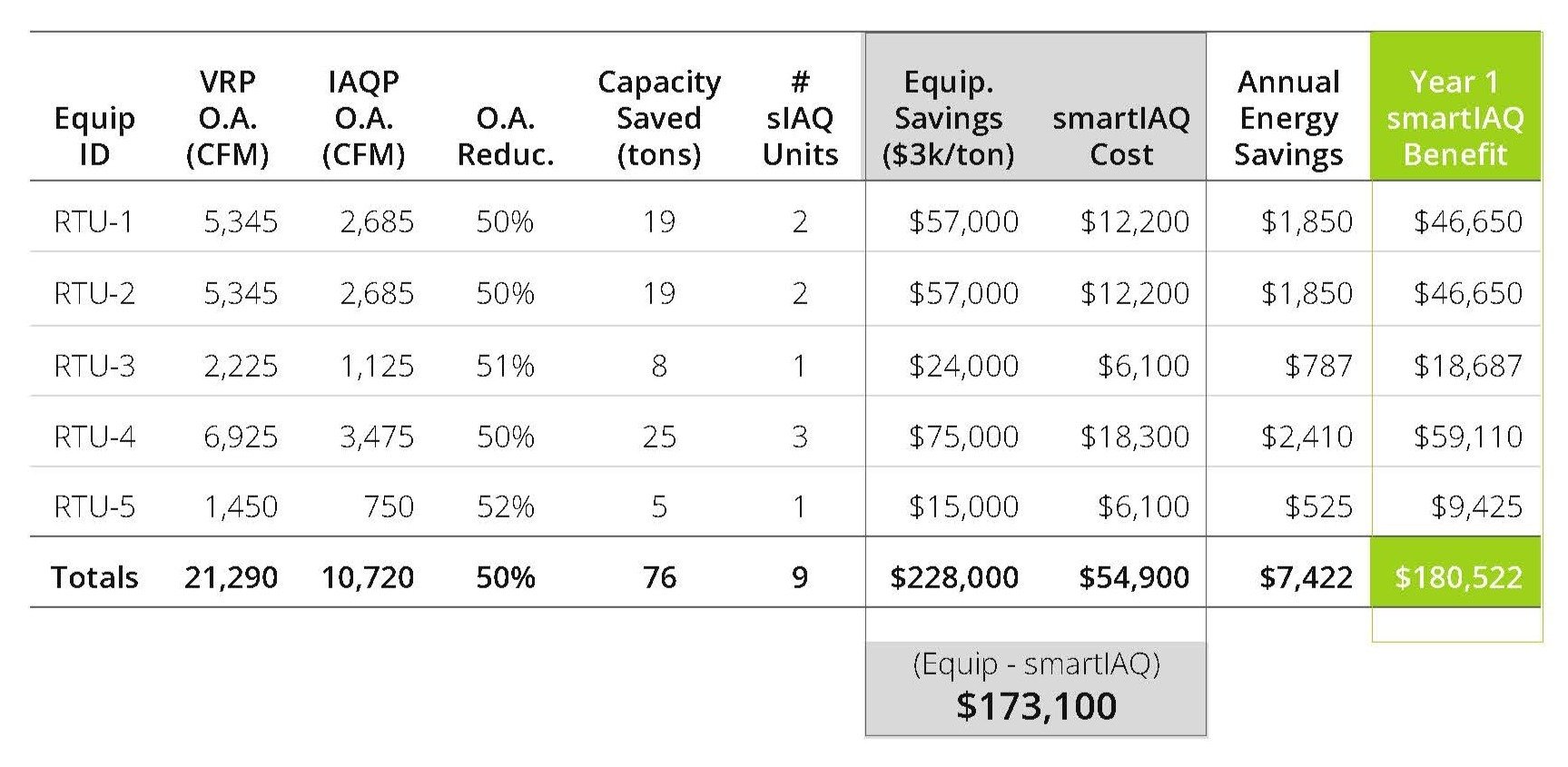

By cutting outdoor air in half, the project eliminated 76 tons of HVAC capacity and saved $173,000 in equipment costs, all while improving air quality. This case study shows how smartIAQ delivers immediate ROI, simplified HVAC design, and ongoing energy savings for high-occupancy spaces.

A Texas church, designed to the VRP, was over budget. Seeking savings, the design team turned to rightsizing ventilation with the Indoor Air Quality Procedure (IAQP). In the revised design, latent load fell as outdoor air was cut in half resulting in a substantial reduction in equipment capacity and energy.

An immediate ROI materialized, duct work remained the same, and the project landed below budget.

Using the smartIAQ Calculator, new ventilation requirements were set for the worship space, vestibule, and meeting rooms. Following IAQP from 62.1-2022, all design compounds were below design limits with smartIAQ in a sidestream configuration. Savings resulted from on-demand air cleaning replacing half of the outdoor air.

| HVAC Coil on Unit 3 | HVAC Coil on Unit 8 | |||

| Bacteria CFU/in2 | Mold-Fungi CFU/in2 | Bacteria CFU/in2 | Mold-Fungi CFU/in2 | |

| Swab 1 | 30,000,000 | 650,000 | 900,000 | 3,400,000 |

| Swab 2 | 20,000,000 | 500,000 | 20,000,000 | 2,800,000 |

| Swab 3 | 3,100,000 | 3,500,000 | 40,000,000 | 30,000,000 |

| Average | 17,700,000 | 1,550,000 | 20,300,000 | 12,066,667 |

This project demonstrates how smartIAQ® transforms ventilation design by aligning with ASHRAE’s IAQP to deliver both compliance and efficiency.

In high-occupancy spaces, peak capacity no longer has to drive oversized HVAC equipment, smartIAQ provides clean air on demand while lowering energy use and design costs.

Beyond a single church, the results highlight how schools, auditoriums, and places of worship can apply this same approach to achieve better air quality with leaner systems and measurable ROI.

Questions?