Executing energy efficient building designs is a never-ending challenge. Gains were made over prior decades via advances in control, LED lighting, and variable speed systems. The pressure mounts again for efficient and sustainable systems.

A sizable energy saving opportunity remains within HVAC system designs. This paper demonstrates that addressing indoor air quality through a standards-based air cleaning approach may reduce initial equipment costs and deliver lower power consumption in many commercial buildings. This approach, called the Indoor Air Quality Procedure (IAQP), allows outdoor airflow to be reduced if indoor air quality can be assured through other means: combining air cleaning with contaminant control.

Reduction of outdoor air, paired with an air cleaning system, is guided by the IAQP as defined in ASHRAE Standard 62.1. This direct approach can provide measurably better indoor air with lower operating and initial equipment cost.

“The IAQP may allow for a more cost-effective solution to providing good air quality.”

ASHRAE 62.1-2019 User’s Manual

Ventilation is necessary for healthy indoor spaces as human and building generated contaminants would eventually render a space toxic if unmanaged. Building codes across the U.S. and Canada, with few exceptions, reference ASHRAE Standard 62.1 Ventilation and Acceptable Indoor Air Quality for code-compliant ventilation designs.

The foreword in 62.1 defines the duality of the role 62.1 plays for air quality and system design:

ASHRAE Standard 62.1 specifies minimum ventilation rates and other measures intended to provide indoor air quality (IAQ) that is acceptable to human occupants and that minimizes adverse health effects…To signify that indoor air quality goes beyond minimum ventilation requirements—and in recognition of those aspects of building systems (equipment, filtration, controls, and more) that contribute to acceptable IAQ—the title of the standard has been updated to “Ventilation and Acceptable Indoor Air Quality.” -Standard 62.1 Foreword

Standard 62.1 offers three approaches to space ventilation. Mechanical ventilation in most buildings will follow either the Ventilation Rate Procedure (VRP) or the Indoor Air Quality Procedure (IAQP).

Ventilation Rate Procedure. The prescriptive design procedure presented in Section 6.2, in which outdoor air intake rates are determined based on space type/application, occupancy level, and floor area, shall be permitted to be used for any zone or system.

Indoor Air Quality Procedure. The IAQP is an alternative to the VRP used to determine the design rate of outdoor airflow to maintain concentrations of design compounds (DCs) and PM2.5 in the indoor environment to be less than design limits (DLs), based on indoor and outdoor sources, air cleaning, and other variables. These outdoor air requirements shall be calculated with mass-balance equations. Verification of occupant satisfaction and indoor DC concentrations shall be performed after the building is completed.

-ASHRAE 62.1 Section 6.1.1 and 6.1.2

The conventional design approach is the prescriptive Ventilation Rate Procedure, in which a mechanical system is sized to include sufficient outdoor air for contaminant dilution. The approach increases HVAC capacity for heating and cooling and is generally the most energy intensive approach with outdoor air capacity sized for worst-case utilization. Controls may be added to regulate outdoor airflow based on population (or other logic) to achieve some energy savings; however, HVAC equipment capacity is selected for the maximum conditions.

"The VPR is an indirect solution to achieving acceptable IAQ. The IAQP is a more direct approach to the goal.”

ASHRAE 62.1-2019 User’s Manual

ASHRAE established the indoor air quality procedure (IAQP) in 1981 as a direct, engineered approach for a more efficient and cost-effective design. The procedure has evolved to become a well-researched and defined alternative to the ventilation rate procedure (VRP). In some cases, the IAQP is the preferred approach. Under the IAQP, HVAC systems can be simplified and right-sized as the outdoor air load is 30 – 75% lower. With reduced load, the system will have lower operating costs compared to a VRP design. Due to these benefits, IAQP is gaining favor for the efficiency, sustainability, and savings it delivers. Example capacity and energy saving scenarios are in Appendix One.

The IAQP is an engineered approach to acceptable indoor air quality. Engineers apply contaminant source control (air cleaners & filters) in concert with lower outdoor air ventilation to deliver a compliant design. In the past the standard required designers to identify contaminant sources, generation rates, steady state concentrations, and air cleaner removal efficiencies. Now the standard is prescriptive and offers designers the options to supplement or modify contaminants and thresholds.

Successful IAQP designs ensure steady state concentrations as calculated in the mass balance equations are below the maximum levels defined in the standard (or by the engineer). The pivotal decisions are the selection of an outdoor air rate and air cleaner. Air cleaner selection is guided by ASHRAE standards and position documents. Automation for this iterative approach is available in ASHRAE’s calculator or calculators from various manufacturers.[2] A comparison between a VRP design and IAQP design for an elementary school classroom is presented in Appendix Two.

As a more direct approach, the IAQP is specific in its intent: maintain the listed design compounds below thresholds recognized by authorities as detrimental to human health. The 15 design compounds (contaminants), including PM2.5, are connected to three pollutant categories: people, building, and outdoor air. People generated contaminants are generally TVOC’s like acetone, acetaldehyde, and phenol. The primary building generated contaminant is formaldehyde. Outdoor air is the primary source for contaminants like ozone and PM2.5. ASHRAE’s calculator defines generation rates for the contaminants by space type, space use, and outdoor airflow based on scientific peer-reviewed research.

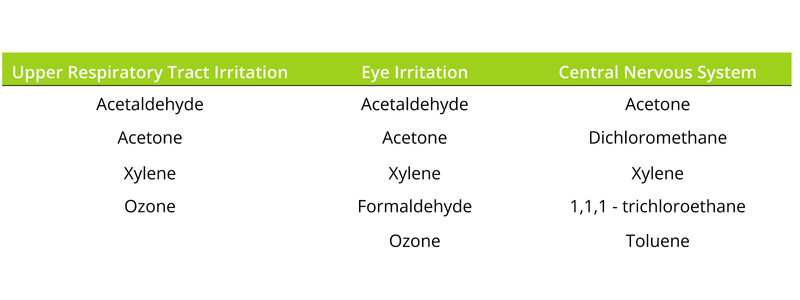

The mass balance process determines compound concentrations at steady state. These levels are compared to the design limits. A ratio of each contaminant concentration to its design limit is calculated. Even if standalone no compound exceeds the design limit, a mixture test is required. That test confirms that human organ system susceptibility to higher concentrations, in combination, do not exceed a healthy limit.

The calculated ratios are added based on the mixtures shown below (found in Section 6.3.3.1). The sum must be less than one. So said differently, under eye irritation, all of the ratios of the design compounds to their limits must be less than one.

.

Effective air cleaners will capture or mitigate contaminant risk in concert with outdoor air dilution, resulting in steady state concentration levels. The magnitude of outdoor air reduction can be substantial (75%) based on system design and space type. This is determined through the mass balance equation where each contaminant steady-state concentration is determined then compared against the concentration design limits defined by ASHRAE (or others). Selecting equipment and dilution rates to keep concentrations within limits is solved iteratively in that calculation.

A variety of mass balance equations exist because the equation needs to match the system designed, whether single or multi-zone, VAV or constant volume. An example mass balance for the system shown follows.

Calculate the concentration of each contaminant (one at a time) in the Breathing Zone (Cbz).

.

Converting the equation into words; the concentration is the quotient of all the contamination sources and their generation rates divided by the cleaning capacity of the system.

Find a selection of mass balance equations from ASHRAE Standard 62.1 in Appendix Three.

.

The industry, particularly ASHRAE, is increasing support for IAQP because it is a more energy efficient and effective approach. Lowering outdoor air delivers two potential economic benefits:

Regarding equipment savings, or initial cost offsets, there are both the direct and indirect benefits of the IAQP to be considered. Initial equipment capacity under the VRP includes the conditioning load for all air in the system, which includes recirculated and outdoor air. It stands to reason that a 50%+ reduction of outdoor air can have a substantial impact on system sizing, particularly considering the summer and/or winter design day. Furthermore, by reducing equipment capacity you reduce equipment size and power draw. In some locations, by reducing outdoor air load on the system, it is possible to avoid energy recovery systems, local code depending.

Projects with higher sustainability goals benefit by reducing conditioning load through the multiplicative benefit of reducing geothermal, solar, wind or other sustainable capacity as it will be less required. Said differently, one Watt-dollar saved on the HVAC via IAQP might be worth tens of Watt-dollars of generation capacity and associated costs.

Multiple calculators, including one from the US Department of Energy may help determine the potential energy savings.[6] This tool was used to determine the kWh/cfm used in Appendix One calculations.

Outdoor air ventilation is the primary means of regulating CO2 concentration. While CO2 is not a design compound under 62.1, designers are cognizant of potential CO2 level rise from human respiration. While outdoor CO2 levels have increased since the industrial revolution to over 420ppm around the world, it still represents 0.04% of outdoor air. Such low outdoor concentration means indoor concentrations are diluted with a small amount of outdoor air. The definition of “unhealthy” levels of CO2 is difficult to assess as direction from ASHRAE, third parties, international agencies, National Institute of Occupational Safety and Health (NIOSH) approach the topic differently. ASHRAE does not have an explicit position and does not consider CO2 a design compound for that reason. [7]

-ASHRAE Position Document on Indoor Carbon Dioxide

ASHRAE does recommend specific CO2 thresholds over ambient for activating demand control ventilation [8]. The following points may be helpful, while the industry monitors ASHRAE’s guidance on this topic.

Mechanical ventilation design is critical for a healthy building. Design choices have meaningful implications for energy, sustainability, and first cost. As designers consider the traditional choice of VRP versus the emerging preference for the IAQP it is helpful to consider how ASHRAE continues to evolve the standard, as documented in Appendix Four.

Advances in technology and standardization support a refreshed evaluation of the IAQP. Owners seek to unlock capital and reduce operating costs through construction and maintenance intervals. In the end, cost effective, code compliant and acceptable indoor air quality is the priority, and the IAQP remains a direct approach to that achieving the goal.

Download PDF to review the appendices.